|

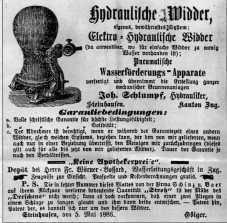

History of Hydraulic Ram Schlumpf Innovations - Professional Ram Manufacturer Since 1885

|

||

|

The principle of the first self-actuating hydraulic ram was invented by Montgolfier brothers, which were also well known for a number of other pioneering inventions (most notably the hot air balloon). Their patent for the hydraulic ram is dated in 1796. It was only in the second half of the 19th Century that quality materials capable of supporting higher pressures became available. This inspired tinkerers and inventors all over the world to develop and produce hydraulic rams independently (modern communication tools were not available at that time!). One of them, Johann Georg Schlumpf, built the first Schlumpf ram in 1885. The phenomenal feature of his ram was its maintenance-free mode of operation, requiring neither ventilation nor air evacuation. Among the many manufacturers who built hydraulic rams at the turn of the 20th century, Schlumpf may be the only one still manufacturing hydraulic rams. And the only one that has continued to refine hydraulic rams to reach higher performance levels. |

|

|

Schlumpf Hydraulic Ram - Year 1890 |

|

|

Schlumpf Hydraulic Ram 1/05 (1905): Easy, practical, and reliable!Even today, thousand of these little wonders are still in use. |

|

|

Schlumpf Hydraulic Ram 1/23 (1923): In 1923, this model of the Schlumpf ram was made with improved adjustability, the best option to deal varying flow rates. Even today, all the spare parts for all this model are in Schlumpf's stock!! |

|

|

Schlumpf Hydraulic Ram 1/2000 (1990): 1990, the outlook of hydraulic ram gets a more modern design, but the same proven valves are on the inside! Schlumpf reliability: A dependable design for waste and delivery valves taht has remained unchanged since 1923 ensures simple, reliable, and inexpensive servicing. |

|

|

1992: The first Schlumpf ram built based on the "Schlumpf Principle" (pressure/shock-free environment in drive pipe between source to ram by increasing the working speed of valves to reduce the working load of valves per beat): The first ram using "Schlumpf Principle" has capacity of pumping around 110,000 liters water 168 meter uphill per day. There was a 4" drive pipes built between source and ram combining with a Pelton turbine, so-called Johnson-pump, both were prone to malfunction due to the greatly quartz sand contained water. Since the existed drive pipe was virtually inaccessible in the rough terrain, therefore this is also the first Schlumpf ram station has adopted the design of spiral drive pipe which was assembled directly to the ram on site. Throuhg this important experiment, several new generation high performance, high capacity hydraulic rams have been built upon this new Schlumpf technic theories afterwards. All of these high performing rams are able to pump water up to 500 meters. The so-called Schlumpf "Compact Ram"concludes all the necessary components, pipes and ram all in one concreted cube. |

|

|

Detail of a Schlumpf "Compact Ram", model built in 2009. | |